Medical equipment quality is a critical factor in healthcare delivery systems. Medical devices and instruments directly influence diagnostic accuracy, treatment effectiveness, and patient safety outcomes.

Healthcare facilities that utilize high-quality equipment demonstrate measurable improvements in operational efficiency and clinical performance metrics.

Quality standards in medical equipment manufacturing establish the foundation for reliable diagnostic procedures, therapeutic interventions, and continuous patient monitoring systems. In Saudi Arabia’s expanding healthcare sector, adherence to rigorous quality specifications for medical devices is essential for maintaining clinical standards. Defective or substandard equipment can result in diagnostic errors, treatment failures, and patient safety incidents.

Healthcare administrators must implement quality assurance protocols to ensure medical equipment meets established safety and performance requirements for optimal patient care delivery.

Regulatory Standards and Requirements for Medical Equipment

Navigating the regulatory landscape is a critical aspect of medical equipment manufacturing. In Saudi Arabia, the Saudi Food and Drug Authority (SFDA) plays a pivotal role in establishing and enforcing regulations that govern the safety and efficacy of medical devices. Understanding these regulations is not just about compliance; it’s about ensuring that the products we bring to market are safe for use and effective in their intended applications.

The SFDA’s guidelines encompass a wide range of requirements, from pre-market approvals to post-market surveillance. As healthcare leaders, we must stay informed about these regulations to ensure that our facilities are compliant and that our patients receive the highest standard of care. This involves not only adhering to local regulations but also aligning with international standards such as ISO 13485, which focuses on quality management systems for medical devices.

By embracing these standards, we can enhance our credibility and foster a culture of safety and quality within our organizations.

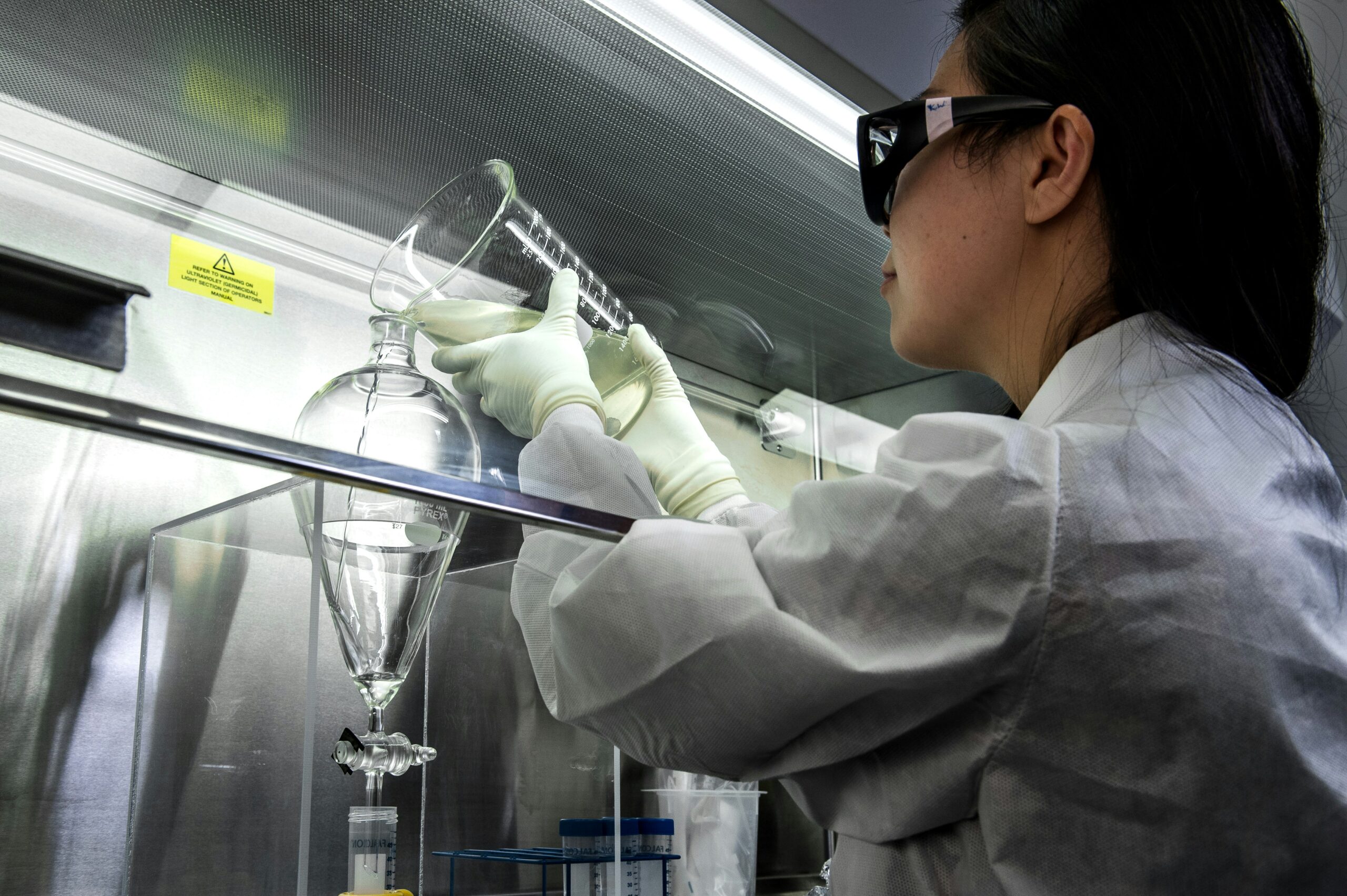

Quality Control Processes in Medical Equipment Manufacturing

Quality control processes are the backbone of effective medical equipment manufacturing. These processes ensure that every device produced meets the established standards for safety and performance. As administrators, we must implement robust quality control measures that encompass every stage of production, from design to final inspection.

This holistic approach not only minimizes risks but also enhances operational efficiency. One effective strategy is to integrate quality control into the manufacturing process itself rather than treating it as a separate function. By adopting methodologies such as Total Quality Management (TQM) or Six Sigma, we can create a culture of continuous improvement where every employee is empowered to contribute to quality assurance.

This proactive stance not only reduces defects but also fosters a sense of ownership among staff, ultimately leading to better patient outcomes.

Testing and Validation of Medical Equipment

Testing and validation are critical components of the medical equipment manufacturing process. Before any device reaches the market, it must undergo rigorous testing to ensure its safety and efficacy. This involves a series of evaluations that assess everything from mechanical performance to biocompatibility.

As healthcare leaders, we must advocate for comprehensive testing protocols that leave no stone unturned. Validation is equally important; it confirms that the equipment performs as intended in real-world scenarios. This process often includes clinical trials and user feedback, which provide invaluable insights into how devices function in practice.

By prioritizing thorough testing and validation, we can mitigate risks associated with device failures and enhance patient safety. It’s essential to foster collaboration between manufacturers and healthcare providers during this phase to ensure that the equipment meets the actual needs of end-users.

Importance of Material Selection and Traceability in Medical Equipment Manufacturing

The selection of materials used in medical equipment manufacturing is a critical factor that directly influences product quality and safety. As healthcare administrators, we must recognize that not all materials are created equal; some may pose risks to patients or fail to meet regulatory standards. Therefore, it is imperative to choose materials that are biocompatible, durable, and suitable for their intended use.

Traceability is another vital aspect of material selection. It allows manufacturers to track the origin and history of materials used in their products, ensuring accountability throughout the supply chain. In the event of a product recall or safety concern, traceability enables swift action to protect patients and maintain trust in our healthcare systems.

By emphasizing material selection and traceability, we can enhance the overall quality of medical devices while safeguarding patient health.

Role of Technology and Innovation in Ensuring Quality in Medical Equipment Manufacturing

In today’s fast-paced healthcare environment, technology and innovation play a crucial role in ensuring quality in medical equipment manufacturing. Advanced technologies such as artificial intelligence (AI), machine learning, and automation are transforming how devices are designed, produced, and tested. As healthcare leaders, we must embrace these innovations to enhance our manufacturing processes and improve product quality.

For instance, AI can be utilized to analyze vast amounts of data from testing processes, identifying patterns that may indicate potential issues before they arise. Automation can streamline production lines, reducing human error and increasing efficiency.

By integrating these technologies into our operations, we can not only improve quality but also reduce costs and time-to-market for new devices.

It’s essential to foster a culture of innovation within our organizations, encouraging teams to explore new technologies that can elevate our manufacturing practices.

Training and Education for Medical Equipment Manufacturing Personnel

The success of any medical equipment manufacturing operation hinges on the skills and knowledge of its personnel. As healthcare administrators, we must prioritize training and education for our teams to ensure they are equipped with the latest industry knowledge and best practices. This investment in human capital is essential for maintaining high-quality standards throughout the manufacturing process.

Training programs should encompass a wide range of topics, including regulatory compliance, quality control processes, and emerging technologies in medical device manufacturing. By fostering a culture of continuous learning, we empower our employees to take ownership of their roles in ensuring product quality. Additionally, mentorship programs can facilitate knowledge transfer between experienced professionals and newer team members, creating a cohesive workforce dedicated to excellence.

Continuous Improvement and Quality Assurance in Medical Equipment Manufacturing

Continuous improvement is a fundamental principle that should guide every aspect of medical equipment manufacturing. As healthcare leaders, we must cultivate an environment where feedback is encouraged, and processes are regularly evaluated for effectiveness. This commitment to continuous improvement not only enhances product quality but also fosters innovation within our organizations.

Implementing quality assurance frameworks such as Plan-Do-Check-Act (PDCA) can help us systematically identify areas for improvement and track progress over time. Regular audits and assessments should be conducted to ensure compliance with regulatory standards and internal quality benchmarks. By embracing a mindset of continuous improvement, we can adapt to changing market demands while maintaining our commitment to patient safety and care excellence.

In conclusion, the journey toward high-quality medical equipment manufacturing is multifaceted and requires a strategic approach from healthcare leaders in Saudi Arabia. By prioritizing quality at every stage—from material selection to personnel training—we can enhance patient outcomes and build trust within our communities. Embracing innovation and fostering a culture of continuous improvement will position us as leaders in the healthcare sector, ultimately benefiting both patients and providers alike.

FAQs

What is quality control in medical equipment manufacturing?

Quality control in medical equipment manufacturing refers to the systematic processes and procedures used to ensure that medical devices meet specified standards of safety, reliability, and performance before they reach the market.

Why is quality control important in medical equipment manufacturing?

Quality control is crucial because medical equipment directly impacts patient health and safety. Ensuring high-quality standards helps prevent device malfunctions, reduces risks, and complies with regulatory requirements.

What are common quality control methods used in medical equipment manufacturing?

Common methods include visual inspections, functional testing, calibration, material verification, process validation, and final product testing to ensure devices meet design specifications and regulatory standards.

Which regulatory standards govern quality control in medical equipment manufacturing?

Key regulatory standards include ISO 13485 for quality management systems, FDA regulations in the United States, and the Medical Device Regulation (MDR) in the European Union, among others.

How does quality control affect the manufacturing process of medical equipment?

Quality control helps identify defects early, ensures consistent production quality, reduces waste, and improves overall efficiency by maintaining strict adherence to design and safety standards throughout the manufacturing process.

What role does documentation play in quality control for medical equipment?

Documentation is essential for traceability, compliance, and accountability. It records all quality control activities, test results, and corrective actions, which are critical for audits and regulatory submissions.

How often is quality control performed during medical equipment manufacturing?

Quality control is performed at multiple stages, including incoming material inspection, in-process checks, and final product testing, to ensure continuous compliance throughout the manufacturing cycle.

Can quality control prevent medical equipment recalls?

While quality control significantly reduces the risk of defects, it cannot guarantee zero recalls. However, effective quality control minimizes the likelihood of product failures that could lead to recalls.

Who is responsible for quality control in medical equipment manufacturing?

Quality control is typically managed by a dedicated quality assurance team within the manufacturing organization, working in collaboration with production, engineering, and regulatory departments.

What technologies are used to enhance quality control in medical equipment manufacturing?

Technologies such as automated inspection systems, computer-aided testing, statistical process control software, and real-time monitoring tools are commonly used to improve accuracy and efficiency in quality control.

No Comments